Derived from German technology and improved, it is energy-saving, efficient, and environmentally friendly.

The self-help patented design of the heat recovery device can save energy by 12% to 15%.

Clean every 3 months.

Intelligent self inspection system for easy maintenance.

Fully automatic PLC control, powerful historical memory system, convenient operation and management.

Technica data

Finishing woven fabric

Finishing knitted fabri

Finishing woven fabric and knitted fabrice

Nominal width 180cm-320cm

The minum working width : 60cm

Available chamer quantity : 8-12F

The maximum temperature of the chamber : 220C

Fabric delivery chain : high tenacity chain

Speed : 5-100m / min

The function of stenter

Dehydration

Finishing

Drying

Curing

Heat-setting of fhe woven fabric and knitted fabric

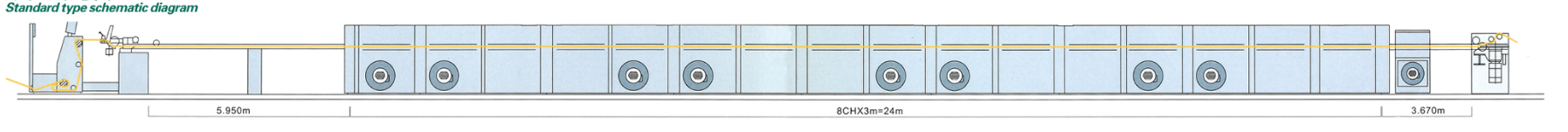

Standard type schematic diagram 5.95m+(8CH*3m=)24m+3.67m

Nozzle Features

Adopt double tilting nozzle , makes cloth heated evenly

Adjust the air volume of the up and down nozzle , makethe cloth is suspended in the air , after processing volume expansion , feel is good

Oven heating device (natural gas)

- 1 burner per box (MAXON)

- 1 set of temperature control parts per case, each set includes temperature probe, PLC control module, setting temperature and controlling display on touch screen

- 1 T-type combustion tube per box (special stainless steel)

- 1 straight burning tube per box (special stainless steel)

- 1 set of filter, vacuum, electric control valve group per box

Widening cold air device

- 1 set of widened cooling air nozzle

- 1 set of cold air source motor [No. 621-5.5kw]

- Air intake can be manually adjusted

- The amount of upper and lower air nozzle can be manually adjusted

Fabric Exit Assembly

- 1 set of needle removal plate in front of needle removal roller

- 2 guide rollers in front of the drawing roller

- 1 drawing roller, 3 kw (Siemens Germany) motor independent drive, equipped with frequency converter

The output tension is stepless and adjustable

- 4 cloth guide rollers

- 1 drop traction roller, 1.5kw(Siemens Germany) motor independent drive, with inverter

Adjustable tension from out cloth to down cloth

- 1 set of open width pushing device, 1.5kw(Germany Siemens) motor independent drive, with frequency converter

The width of open width is adjustable

- 1 set of high efficiency static elimination device

CN

CN