YOH-300D/350D High Temperature Low Liquor Ratio Overflow Dyeing Machine Series

Machine Features

1 . Low Liquor ratio

Liquor ratio can reach 1 : 5

2 . Homogeneous staining device

The specially designed dosing system can ensure the homogeneous staining results in low liquor ratio dyeing.

3 . High reproducibility

Programmable metering water supply system , precisely quantitative dosing system , control of fabrics cycle time and adjustable nozzle pressure ensure the reproduction quality of fabrics.

4 . Superior fabric surface quality

Due to low liquor ratio, fabric brings less water when running, which reduces the fabric weight and thereby reduces the fabric tension which leads to fuzziness by rubbing. This not only improvest the surface quality of fabrics but also reduces the shringkage rate.

5. Engergy-saving and efficient

1 ton cotton fabric dyeing cost 50-60 ton water, which saves 50% water and over 40% auxiliaries and steam.

6 . Separate water supply cleaning system

With a separate water supply cleaning system, the water pressure can be higher and stronger and tank washing will be faster and cleaner.

7 . Fabric storage tank with a load adjusting system

Use the design of fabric storage tank with a load adjusting system, whatever the fabric is thick or thin , the capacity is big or small, also can be normal dyeing.

8 . High degree of automation

The powerful formula management system, historical record system and intuitional real-time trend monitoring system of the touch-screen computer make the machines’s operation management and maintenance quick and easy.

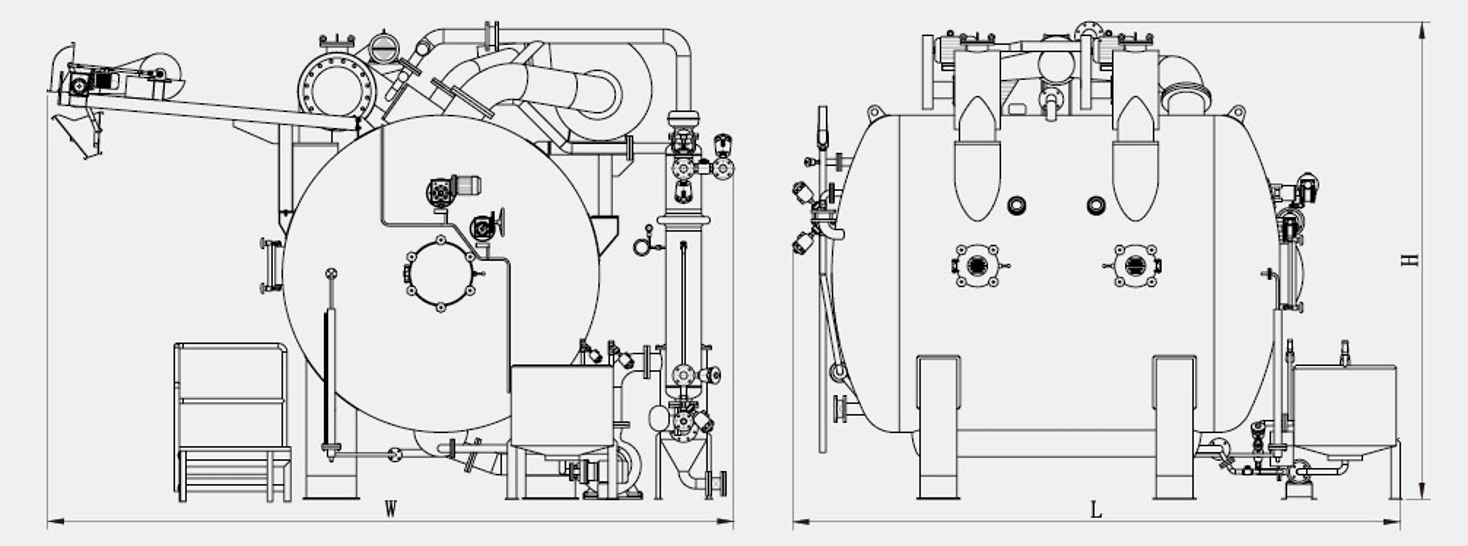

Model | Tube | Capacity | Power | Dimensions (length * width * height) | |||

Kg | Pound | Kw | mm | in | |||

YOH-300D | YOH-300D-1T | 1T | 300 | 660 | 13.12 | 3405*5080*3710mm | 134*200*146in |

YOH-300D-2T | 2T | 600 | 1320 | 21.37 | 4825*5230*3710mm | 190*206*146in | |

YOH-300D-3T | 3T | 900 | 1980 | 31.72 | 6350*5385*3710mm | 250*212*146in | |

YOH-300D-4T | 4T | 1200 | 2640 | 38.12 | 8150*5385*3710mm | 320*212*146in | |

YOH-300D-6T | 6T | 1800 | 3960 | 57.5 | 11100*5485*3810mm | 433*216*150in | |

YOH-300D-8T | 8T | 2400 | 5280 | 71.3 | 13970*5485*3810mm | 550*216*150in | |

YOH-350D | YOH-350D-1T | 1T | 350 | 770 | 13.12 | 3405*5080*3685mm | 134*200*145in |

YOH-350D-2T | 2T | 700 | 1540 | 21.37 | 4825*5230*3685mm | 190*206*145in | |

YOH-350D-3T | 3T | 1050 | 2310 | 31.72 | 6350*5385*5385mm | 250*212*147in | |

YOH-350D-4T | 4T | 1400 | 3080 | 38.12 | 8150*5385*5385mm | 320*212*147in | |

YOH-350D-6T | 6T | 2100 | 4620 | 57.5 | 11100*5485*5485mm | 433*216*151in | |

YOH-350D-8T | 8T | 2800 | 6160 | 71.3 | 13970*5485*5485mm | 550*216*151in | |

Form Chart

Standard Configuration :

Standard Configuration :

1. Machine pressure vessel and major wet parts are made of 316L high corrosion-resistant stainless steel

2. Teflon-lined fabric chamber

3. Frequency-controlled pump motor

4. Frequency-controlled interal winch

5. Frequency-controlled vario-plaiter

6. Fabric loading / unloading winch

7. The tangling released device

8. Automatic adjustable chamber

9. Internal spraying and rinsing system

10. High-efficiency cartridge heat exchanger

11. Quantitative dosing system

12. Proportional heating and cooling system

13. Electromagnetic water meter

14. Automatic self cleaning filter system

15. Automatic electric cabinet

16. Stainless steel working platform

Technical Parameter :

Liquor ratio can reach 1:5

Maximum running speed of fabric lifting roller: 420r/min

Maximum working temperature : 140℃

Maximum working pressure : 0.33MPa

Heating rate : 20℃ to 100℃ average 5℃/min;

100℃ to 130℃ average 2.5℃/min

( The dry saturated steam pressure is 0.7Mpa )

Cooling rate : 130℃ to 60℃ average 2.5℃ / min

( cooling water at 3bar , 25℃ )

Options:

1. Programmable second water inflow and drainage

2. Fabric seam detector

3. Second charging barrel with separate dosing pump valves and stirrer

4. The reserved tank is designed according to a capacity proportion of 1:4.5

CN

CN